How to make your plastic products in the USA

Need volume production of your plastic parts in the USA?

Here’s how to get it done.

Getting parts made in the USA shortens lead times, improves product marketing, and lowers carbon footprint. But getting started can be a challenge.

So we prepared a useful guide for the savvy product owner to get their parts made in volume.

From 3D Printing to Molded Production

3D printing makes prototyping and product development massively faster. But as a product scales, how do you know when to switch to mass production methods?

Timelines

Injection molding produces parts very fast, but there’s a longer project time to the first part. What’s a typical project timeframe?

Recycled and post-consumer resins

The modern consumer prefers brands that are good environmental stewards. How do you make your plastic product sustainable?

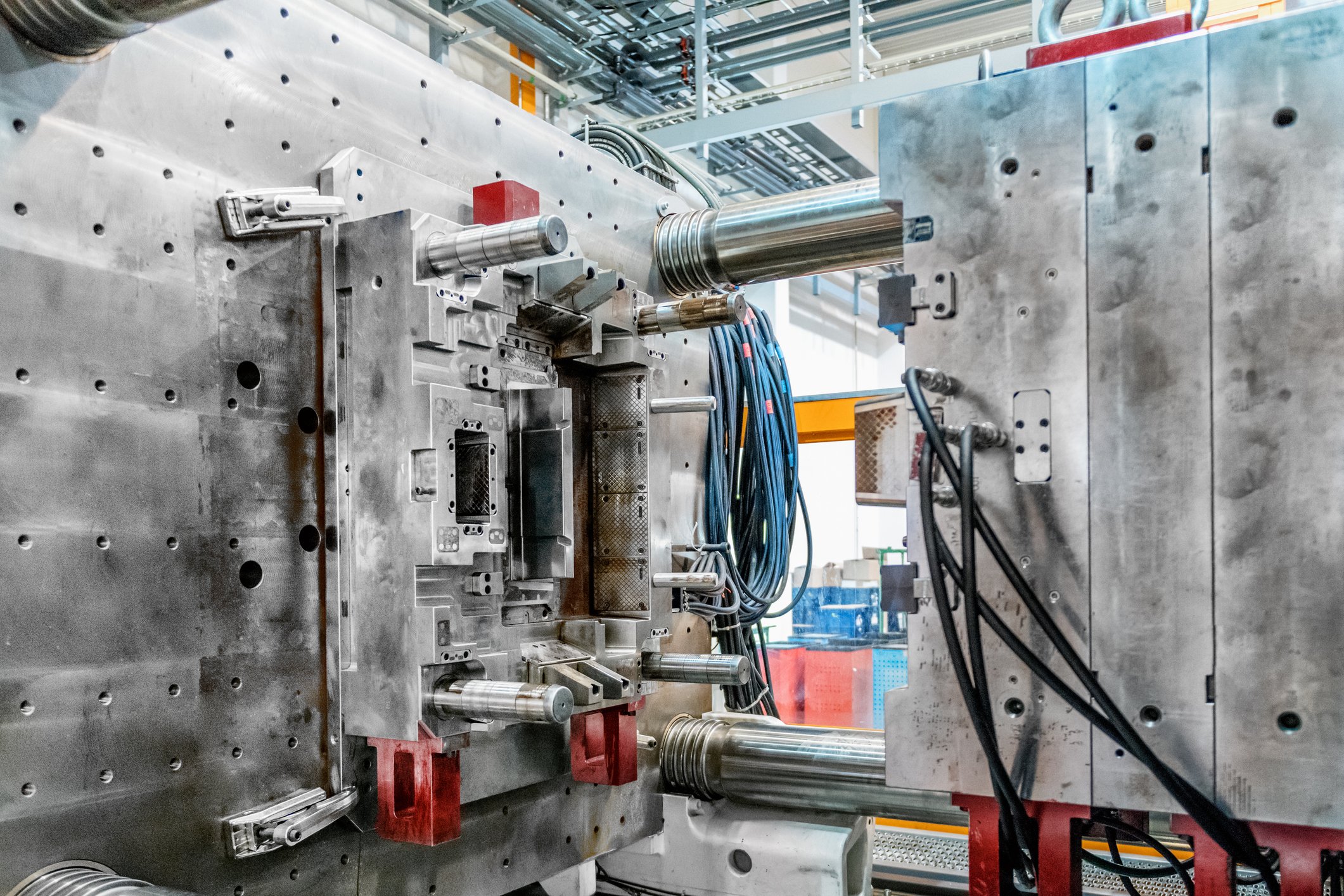

The Cost of a Mold

It’s the big question: what does it cost to get a mold made? Exact answers require a lot of pre-engineering work. But this rough guide can help you with typical budgets.

Estimating Part Cost

What’s a typical injection molded part cost? What are the factors that affect it? While exact answers depend on technical specifics of a part and services required, this guide tells you what goes into the cost of a finished part.

From Idea to Shipment

You’ve got an idea. What’s the practical path to your product rolling off the production floor and being shipped to your customers?

Key Supplier Questions

An honest molder will tell you that choosing a supplier is a matter of finding the right fit for the right project: there is no one supplier that’s the right fit for all projects. What are the questions to ask to find the right partner to make your product?